Ceramic Coating for Motorcycles, RVs, and Boats: Special Considerations for Different Surfaces, Saltwater, and UV Protection

Your $40,000 boat is sitting in the marina, and you just noticed the gelcoat starting to chalk. Your RV's fiberglass looks dull after a summer of road trips. Your motorcycle's paint has lost that showroom shine after just one season.

Sound familiar?

Here's what most owners don't realize: standard wax and sealants weren't designed for the punishment that motorcycles, RVs, and boats endure. Between saltwater exposure, relentless UV rays, and constant environmental abuse, these vehicles need something stronger.

That's where ceramic coating for motorcycles, RVs, and boats comes in. This isn't your typical car protection. We're talking about nano-ceramic technology that bonds to different surfaces—from motorcycle paint and chrome to RV fiberglass and boat gelcoat—creating a shield against the elements that can last for years.

At Fresh Layer, we've applied ceramic coatings to hundreds of motorcycles, RVs, and boats across San Diego County. We've seen firsthand how the right coating prevents oxidation on boat gelcoat, stops RV fiberglass from chalking, and keeps motorcycle chrome looking new. More importantly, we've learned that not all coatings work the same way on different surfaces.

This guide breaks down everything you need to know about protecting your motorcycle, RV, or boat with ceramic coating, including the special considerations that most detailers won't tell you about.

What Is Ceramic Coating and How Does It Work?

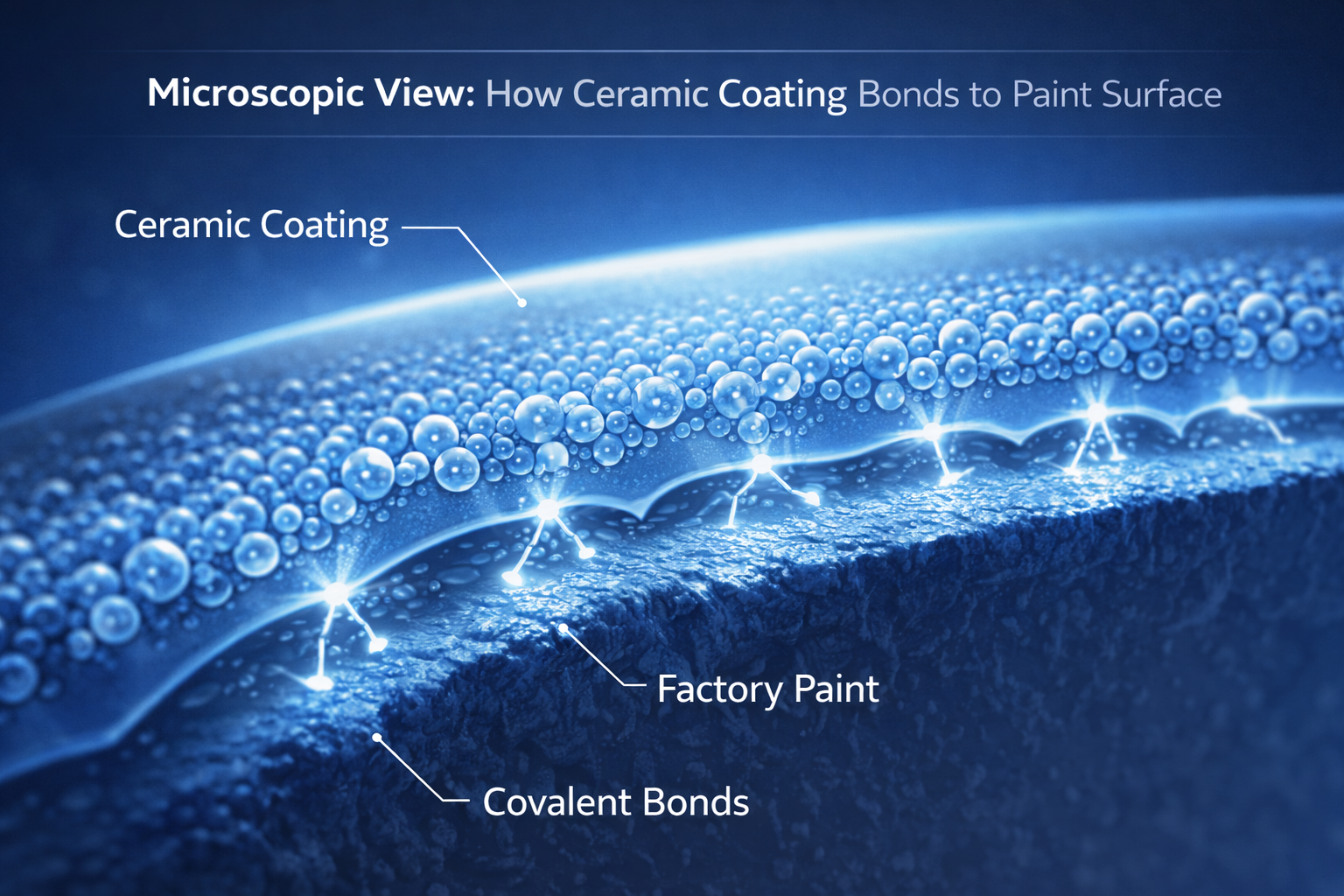

Ceramic coating is a liquid polymer containing silicon dioxide (SiO2) that chemically bonds to your vehicle's surface at the molecular level. Once cured, it creates a permanent protective layer that's significantly harder and more durable than traditional wax or sealants.

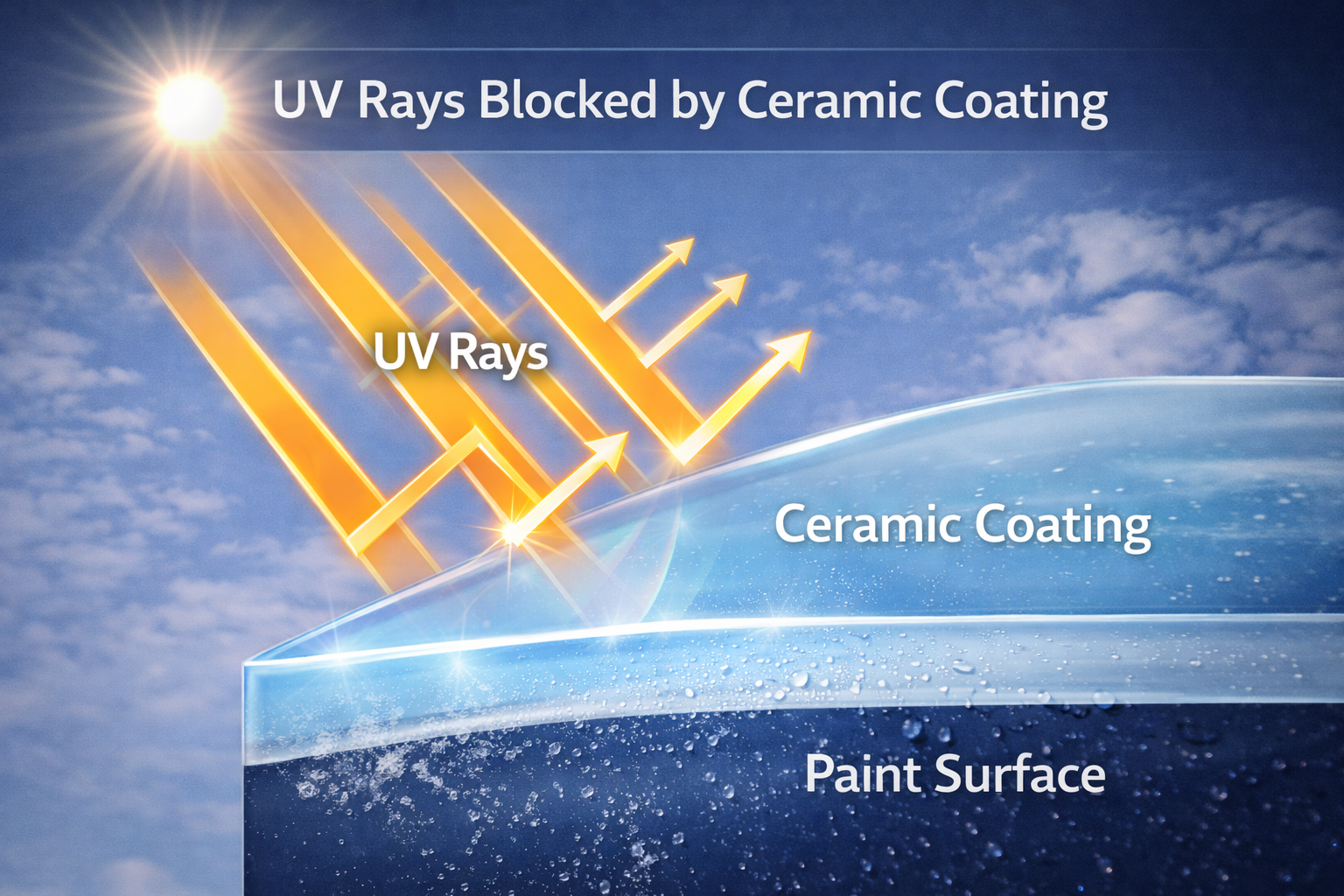

Think of it as a second clear coat that repels water, resists chemicals, and blocks UV rays.

Here's what makes nano-ceramic coating different:

Chemical bonding instead of sitting on top of the surface

Hydrophobic properties that cause water to bead and sheet off

9H hardness rating that resists scratches and swirl marks

UV blocking that prevents oxidation and fading

Chemical resistance against acids, salts, and environmental contaminants

The "nano" part refers to the microscopic particles in the formula that fill in surface imperfections, creating an incredibly smooth, glass-like finish.

For motorcycles, RVs, and boats, this technology is particularly valuable because these vehicles face environmental challenges that cars rarely encounter.

Why Motorcycles, RVs, and Boats Need Different Protection Than Cars

Your car sits in a parking lot. Your motorcycle, RV, and boat live completely different lives.

Motorcycles face:

Direct road debris impact with no body protection

Chrome and aluminum surfaces that corrode faster than paint

Constant exposure to bugs, rain, and temperature extremes

Higher speeds that increase environmental damage

RVs deal with:

Massive surface area exposed to sun for months

Fiberglass and gelcoat that oxidize faster than automotive paint

Storage outdoors in all weather conditions

Trees, birds, and industrial fallout during travel

Boats endure:

Saltwater immersion and spray

Constant moisture and humidity

Intense UV reflection off water

Marine growth and organic contamination

Gelcoat degradation unique to watercraft

Standard automotive wax lasts maybe 6-8 weeks on a car. On a boat in saltwater? You're lucky to get 2 weeks. On an RV parked in the desert sun? The wax will literally bake off within days.

This is why ceramic coating for motorcycles, RVs, and boats isn't just beneficial—it's essential for anyone who wants to protect their investment long-term.

Ceramic Coating Benefits for Motorcycles

Motorcycle ceramic coating delivers protection that standard products simply can't match.

Paint Protection That Actually Lasts

Your motorcycle's paint takes a beating. Every ride throws rocks, bugs, and road grime directly at exposed surfaces. Ceramic coating creates a sacrificial layer that absorbs this abuse instead of your paint.

The hydrophobic properties mean bugs and tar slide off easier during washing. No more scrubbing to remove baked-on insects from your fairings.

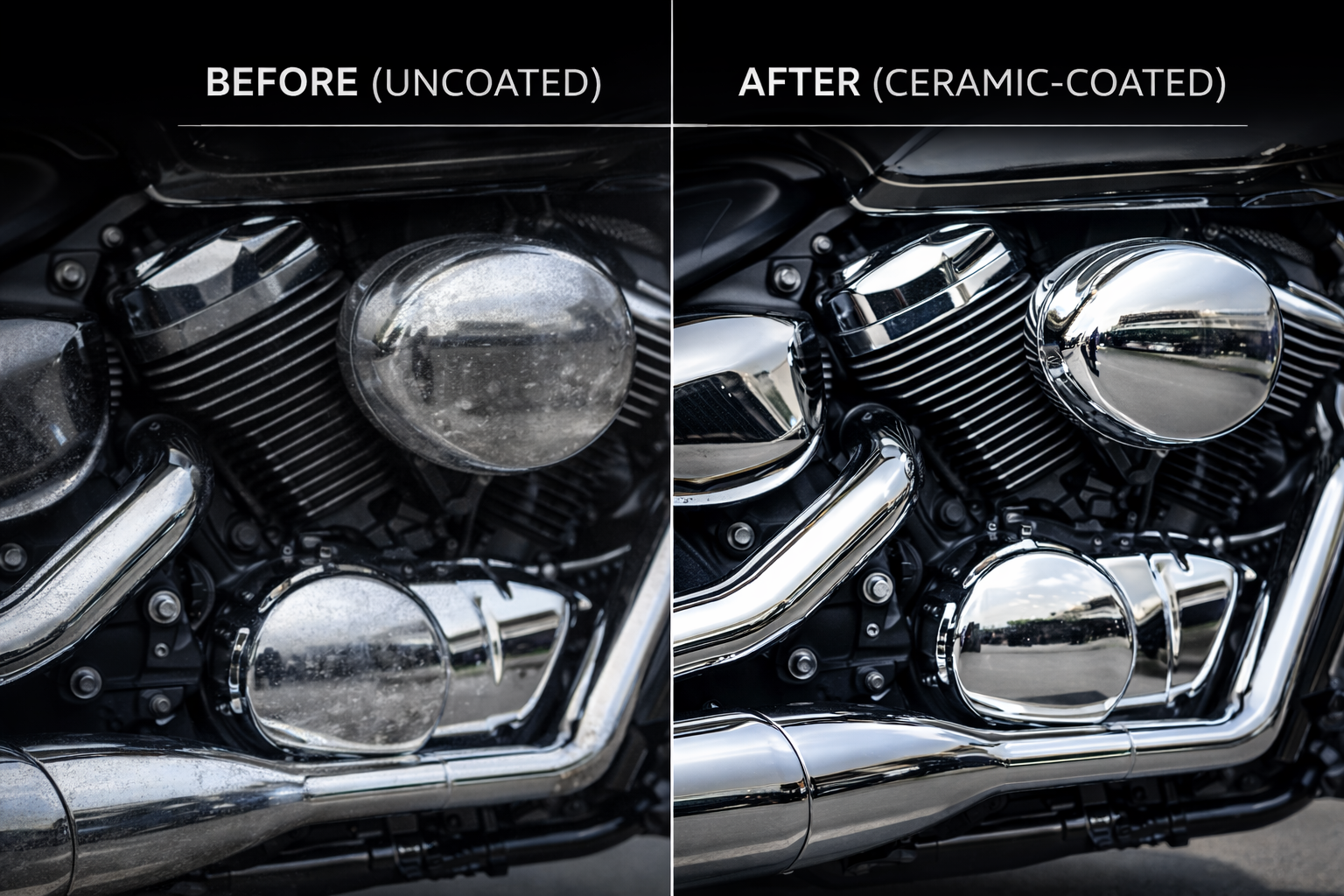

Chrome and Metal Surface Protection

Here's what most riders don't know: ceramic coating works on chrome, aluminum, and polished metal surfaces too.

Chrome exhaust pipes, engine cases, and wheels develop oxidation and pitting from road salt and moisture. A nano-ceramic coating prevents this by creating a barrier against corrosive elements.

We've seen chrome pipes on coastal bikes stay spotless for 2+ years with proper coating, while untreated chrome showed rust within 6 months.

Benefits for Riders

Easier cleaning - dirt and grime wipe off with minimal effort

Enhanced appearance - deeper gloss and color depth

Reduced oxidation on all metal surfaces

Better resale value - protected bikes command higher prices

Less frequent detailing required

For motorcycles stored outside or ridden in harsh conditions, ceramic coating can extend your bike's pristine appearance by years.

Ceramic Coating Benefits for RVs

RVs present unique challenges that make ceramic coating especially valuable.

Fiberglass and Gelcoat Protection

Most RV exteriors are fiberglass with a gelcoat finish, not automotive paint. Gelcoat oxidizes and chalks much faster than paint, especially in high-UV environments.

That chalky, dull appearance you see on older RVs? That's oxidation eating away at the gelcoat surface. Once it starts, it accelerates. Ceramic coating prevents this oxidation from beginning in the first place.

Massive Surface Area Advantage

An RV might have 800-1,200 square feet of exterior surface. Imagine waxing that by hand every 6 weeks. You won't.

RV ceramic coating lasts 2-5 years depending on the product and conditions. That's one application instead of 20-40 wax sessions over the same period.

Storage Protection

RVs often sit unused for months. During storage, UV rays, tree sap, bird droppings, and industrial fallout attack the surface 24/7.

A properly applied ceramic coating protects your RV during storage better than any cover can. The hydrophobic layer prevents water from sitting on seams and seals, reducing moisture intrusion and potential water damage.

Real-World RV Benefits

Prevents chalking and oxidation on fiberglass and gelcoat

Reduces cleaning time by 60-70% compared to uncoated surfaces

Protects graphics and decals from fading

Maintains resale value significantly better than untreated RVs

Works on rubber roofs with specialized formulations

We've seen 10-year-old RVs with ceramic coating look better than 3-year-old untreated units.

Ceramic Coating Benefits for Boats

If there's one application where ceramic coating proves its worth, it's marine ceramic coating for boats.

The Saltwater Challenge

Saltwater is the most corrosive environment your vehicle will ever face. Salt accelerates oxidation, eats through wax in days, and causes permanent damage to unprotected gelcoat and marine paint.

Boat ceramic coating creates a chemical barrier that saltwater can't penetrate. The coating resists the corrosive effects of salt while preventing organic growth from bonding to the hull.

Gelcoat Preservation

Here's the critical part boat owners need to understand: gelcoat degradation is permanent. Once oxidation starts, you can't reverse it without aggressive compounding that removes material.

Marine-grade ceramic coating stops oxidation before it begins by:

Blocking UV rays that break down gelcoat resins

Preventing moisture intrusion into the gelcoat matrix

Creating a barrier against chemical contamination

Reducing thermal stress from sun exposure

A coated boat hull maintains its factory gloss for years instead of months.

Marine Paint Protection

Boats with painted hulls face similar challenges. Marine paint contains different compounds than automotive paint to handle water immersion. Ceramic coating compatible with marine paint provides:

Superior UV protection against sun reflecting off water

Chemical resistance to fuel, oil, and cleaning products

Reduced bio-fouling and organic growth

Easier bottom cleaning and maintenance

Boat-Specific Benefits

Massive cleaning time reduction - slime and scum wipe off easily

Reduced fuel consumption - smoother hull reduces drag

Less frequent waxing - coating lasts 2-3 years vs wax every 2-4 weeks

Better color retention on colored gelcoat and paint

Prevents waterline staining that's nearly impossible to remove

For boats in saltwater or heavily used freshwater environments, ceramic coating isn't optional if you want to maintain your investment.

Special Surface Considerations: Paint, Chrome, Fiberglass, and Gelcoat

Not all ceramic coatings work the same on different surfaces. This is where professional knowledge becomes critical.

Motorcycle Paint vs Automotive Paint

Motorcycle paint is typically thinner and more delicate than car paint. The prep work must be gentler to avoid burning through paint on curved surfaces and edges.

Chrome and polished aluminum require specific primers or coating formulations designed for non-porous surfaces. Standard ceramic coating won't bond properly to bare metal without proper preparation.

RV Fiberglass and Gelcoat

Fiberglass surfaces are porous compared to paint. The coating needs to fill these pores while bonding to the gelcoat top layer.

Older RVs with oxidized gelcoat require paint correction first. You can't coat over chalky, oxidized surfaces and expect good results. The oxidation must be removed, which reveals fresh gelcoat that accepts coating properly.

Some RV manufacturers use TPO (thermoplastic polyolefin) panels instead of fiberglass. TPO requires different coating chemistry because it's a plastic, not gelcoat.

Boat Gelcoat Specifics

Marine gelcoat is formulated differently than RV gelcoat. It's designed to handle water immersion, which makes it less porous but also more sensitive to improper coating application.

Boat gelcoat considerations:

Must be completely clean and salt-free before coating

Requires specialized prep to remove wax, salt deposits, and oxidation

Benefits from multi-layer coating application for maximum protection

Needs UV-stable coating rated for constant water contact

Marine Paint on Boat Hulls

Bottom paint and topside marine paint have anti-fouling agents and different binders than automotive paint. Not all ceramic coatings are compatible with these specialized paints.

Professional marine ceramic coating products are formulated specifically for compatibility with marine paint systems. Using automotive ceramic coating on a boat with marine paint can cause adhesion failures.

Key Surface Rules

Match coating chemistry to surface type

Never coat over oxidation or contamination

Use metal-specific primers for chrome and aluminum

Verify compatibility with marine paint before application

Consider porosity differences between surfaces

This is why DIY ceramic coating on boats and RVs has such a high failure rate. Surface identification and proper product selection require expertise.

How Saltwater Destroys Unprotected Surfaces (And How Coating Prevents It)

Saltwater doesn't just sit on surfaces—it actively attacks them at the molecular level.

The Science of Salt Corrosion

Salt (sodium chloride) is hygroscopic, meaning it attracts and retains moisture. When salt spray lands on your boat or coastal RV, it creates a constant wet environment even when the surface looks dry.

This trapped moisture causes:

Oxidation acceleration - salt acts as a catalyst for rust and corrosion

Gelcoat matrix breakdown - moisture penetrates into the gelcoat resin

Paint delamination - salt works under paint layers causing bubbling

Metal corrosion - aluminum and chrome pit and corrode rapidly

You'll see this as white chalking on gelcoat, bubbling paint, rust streaks from metal hardware, and eventually structural damage.

How Ceramic Coating Blocks Salt Damage

Marine-grade ceramic coating creates a completely hydrophobic, chemically inert barrier between saltwater and your surface.

Here's what happens:

Saltwater can't penetrate the coating's molecular structure

Water beads and sheets off instead of sitting on the surface

Salt crystals don't bond to the slick coating surface

Moisture can't reach the underlying gelcoat or paint

Corrosion stops before it starts

We've tracked boats with ceramic coating in San Diego's saltwater environment. After 18 months, coated boats showed zero oxidation or salt damage while untreated boats in the same marina showed significant degradation.

Coastal RVs and Motorcycles

If you live near the coast, your RV and motorcycle face the same saltwater challenges. Salt air carries miles inland, especially in areas with consistent ocean breezes.

Coastal motorcycle chrome will pit and corrode within a year without protection. RVs stored near the beach show accelerated gelcoat chalking and metal hardware corrosion.

Ceramic coating provides the same saltwater resistance for these vehicles as it does for boats.

Protection Longevity in Saltwater

Standard wax in saltwater: 2-3 weeks Polymer sealant in saltwater: 1-2 months Professional ceramic coating in saltwater: 2-3 years

The difference is dramatic. One coating application protects longer than 50+ wax applications.

UV Protection: Why It Matters More for RVs and Boats

UV radiation is the silent killer of vehicle surfaces, and RVs and boats get hammered worse than cars.

Why RVs and Boats Face Extreme UV

Cars typically park under shade, in garages, or move frequently. RVs sit in storage lots, driveways, and campgrounds with full sun exposure for months. Boats float in open water where UV reflects off the surface, essentially doubling exposure.

In coastal areas like San Diego, the UV index regularly hits 9-11 (very high to extreme) during summer. That's enough to cause visible damage within weeks on unprotected surfaces.

What UV Does to Different Surfaces

On gelcoat:

Breaks down resin binders causing chalking

Fades colors to pale, washed-out versions

Creates micro-cracks that allow moisture penetration

Accelerates oxidation that dulls the finish

On marine and RV paint:

Causes clear coat failure and peeling

Fades pigments, especially reds and blacks

Creates a dull, lifeless appearance

Makes paint brittle and prone to cracking

On motorcycle paint and chrome:

Fades paint colors rapidly on exposed surfaces

Causes chrome to yellow and lose luster

Damages plastic components like windscreens

Degrades rubber and vinyl trim

How Ceramic Coating Blocks UV Damage

Quality ceramic coating acts as a UV-blocking shield between sunlight and your surface.

The SiO2 formula in ceramic coating has natural UV-blocking properties. Professional marine and RV formulations include additional UV inhibitors that block 99%+ of harmful UV rays.

This protection prevents:

Color fading and pigment breakdown

Resin degradation in gelcoat

Clear coat oxidation and failure

Chalking and surface deterioration

Real-World UV Protection Results

We've tested this extensively in San Diego's high-UV environment:

Coated RVs maintained factory color and gloss after 3 years

Uncoated RVs showed visible fading after 18 months

Coated boats had zero chalking after 2 seasons

Uncoated boats needed compounding within 1 year

The difference is visible and measurable.

UV Protection for Stored Vehicles

If your RV sits in storage or your boat lives on a trailer, UV protection becomes even more critical. These vehicles can't hide from the sun.

Ceramic coating provides 24/7 UV protection that never needs reapplication for years. Compare that to wax or sealant that breaks down within weeks under constant sun exposure.

How Ceramic Coating Extends Gelcoat and Marine Paint Life

This is where ceramic coating proves its real value for boats and RVs.

Understanding Gelcoat Degradation

Gelcoat is a polyester resin surface that's applied over fiberglass. It's designed to be sacrificial—meaning it slowly wears away over time to protect the underlying fiberglass.

The problem: once gelcoat degrades past a certain point, it can't be restored. You're looking at expensive fiberglass repair or complete gelcoat replacement.

The Three Stages of Gelcoat Failure

Stage 1: Surface oxidation (reversible)

Dull appearance and slight chalking

Can be corrected with compounding

This is your warning to protect the surface

Stage 2: Deep oxidation (partially reversible)

Heavy chalking and color fading

Requires aggressive compounding (removes material)

Approaching irreversible damage

Stage 3: Gelcoat failure (irreversible)

Visible cracking and crazing

Water intrusion into fiberglass

Requires complete gelcoat replacement

Ceramic coating prevents stages 1-3 from ever starting.

How Coating Stops the Degradation Process

Gelcoat degrades through four primary mechanisms:

1. UV breakdown - coating blocks 99%+ of UV rays

2. Oxidation - coating prevents oxygen contact with gelcoat surface

3. Chemical attack - coating resists acids, salts, and pollutants

4. Moisture intrusion - hydrophobic barrier keeps water out

By blocking these four attack vectors, ceramic coating essentially freezes gelcoat aging.

Properly coated gelcoat can last 15-20 years looking nearly new. Unprotected gelcoat shows significant degradation within 3-5 years.

Marine Paint Protection Works Similarly

Marine paint on boat hulls faces the same challenges as gelcoat, plus additional stress from water immersion and mechanical cleaning.

Ceramic coating on marine paint:

Prevents oxidation that causes paint to fade and chalk

Blocks chemical attack from fuel, oil, and cleaning products

Reduces bio-fouling adhesion that requires aggressive scrubbing

Maintains color saturation and gloss for years

Prevents waterline staining that etches into unprotected paint

Cost Comparison: Protection vs Replacement

Average gelcoat restoration: $3,000-$8,000 for a mid-size boat

Average RV gelcoat repair: $2,000-$5,000 for significant oxidation

Professional ceramic coating: $800-$2,000 for boats/RVs

The coating costs less than one restoration and prevents the need for any restoration for 3-5+ years.

If ceramic coating extends your gelcoat life by even 5 years, you've saved thousands in restoration costs and avoided the depreciation that comes with visible surface damage.

Application Process: What's Different for Each Vehicle Type

Ceramic coating application follows the same basic steps, but each vehicle type has specific requirements.

Universal Preparation Steps

Thorough decontamination - remove all dirt, grime, wax, and sealants

Clay bar treatment - remove bonded contaminants

Paint/surface correction - remove scratches, oxidation, swirl marks

Final wipe down - ensure completely clean, residue-free surface

Coating application - apply in controlled environment

Curing time - allow proper bonding before exposure

The devil is in the details for each vehicle type.

Motorcycle-Specific Application

Challenges:

Small, intricate surfaces require precision

Multiple surface types (paint, chrome, plastic, rubber)

Hard-to-reach areas behind fairings and components

Key differences:

Use smaller application pads for tight spaces

Tape off rubber and non-coated surfaces carefully

Apply lighter coats on thin motorcycle paint

Use metal-specific primers on chrome and aluminum

Extra care around emblems, badges, and graphics

Application time: 4-8 hours for full motorcycle depending on size and condition.

RV-Specific Application

Challenges:

Massive surface area (500-1,200 sq ft)

Height requires ladders and lifts

Multiple surface types (gelcoat, aluminum, rubber roof)

Often stored outdoors with heavy contamination

Key differences:

Work in sections to prevent coating from curing before buffing

Use extension poles for high areas

Different products for gelcoat vs rubber roofing

More aggressive paint correction often needed on older RVs

Climate control critical—can't coat in direct sun

Application time: 2-4 days for full RV with proper prep.

Boat-Specific Application

Challenges:

Salt contamination must be completely removed

Gelcoat porosity requires more product

Bottom paint can't be coated with topside products

Often needs to be done while boat is in water

Key differences:

Acid wash may be needed to remove heavy salt deposits

Marine-grade coating specifically formulated for water contact

Multiple coats standard for maximum protection

Must address waterline staining before coating

Temperature and humidity control more critical

Application time: 1-3 days depending on boat size and condition.

Climate and Environment Considerations

Temperature: Ideal application is 60-80°F

Humidity: Below 60% relative humidity

Sun exposure: Never coat in direct sunlight

Wind: Indoor or sheltered application only

These requirements are why mobile coating services often struggle with quality results, especially for RVs and boats.

Professional vs DIY: What Works and What Doesn't

The truth about DIY ceramic coating: it's possible, but the failure rate is high, especially on boats and RVs.

Why DIY Often Fails

Common DIY mistakes:

Inadequate surface preparation (causes poor bonding)

Wrong product for surface type (coating fails or doesn't bond)

Incorrect application technique (high spots, streaking)

Poor environmental control (humidity, temperature, dust)

Insufficient curing time (coating washes off prematurely)

We've corrected dozens of failed DIY coatings. The removal and reapplication costs more than professional installation would have cost initially.

When DIY Makes Sense

Good candidates for DIY:

Motorcycles with simple painted surfaces

Small boats (under 20 feet) with good gelcoat condition

Someone with detailing experience

Controlled indoor workspace available

Quality consumer-grade coating products

Required skills:

Paint correction experience

Understanding of surface preparation

Patience for multi-day process

Attention to detail

Proper tools and equipment

When Professional Application is Worth It

Go professional for:

Large RVs (over 25 feet)

Boats over 25 feet

Vehicles with oxidized or damaged surfaces

High-value vehicles ($30,000+)

Motorcycles with custom paint or chrome

Anyone without detailing experience

What Professionals Offer

Professional advantages:

Surface correction expertise - remove oxidation, scratches, swirls

Proper product selection - right coating for specific surfaces

Commercial-grade products - longer lasting than consumer versions

Controlled environment - indoor facilities with climate control

Warranty coverage - guaranteed results and longevity

Insurance protection - covered if something goes wrong

DIY Product Recommendations

If you're determined to DIY, use these quality consumer products:

Ceramic Pro DIY - good for motorcycles and small boats

CarPro Cquartz UK 3.0 - versatile for multiple surfaces

Gtechniq Crystal Serum Light - user-friendly application

Adams Ceramic Coating - budget-friendly option

Avoid cheap Amazon coatings under $30—they're often SiO2 sprays, not true ceramic coating.

Cost Comparison

DIY costs:

Coating kit: $50-$150

Prep materials: $50-$100

Tools (if needed): $100-$200

Time investment: 15-30 hours

Total: $200-$450 plus significant time

Professional costs:

Motorcycle: $400-$800

RV: $800-$2,500

Boat: $800-$3,000

Total: Guaranteed results with warranty

The professional cost includes prep, correction, quality products, and expertise. For most people, it's worth the difference.

Cost Breakdown: What to Expect

Understanding ceramic coating costs helps you budget and avoid overpaying.

Motorcycle Ceramic Coating Costs

Basic package (paint only): $400-$600

Tank, fairings, fenders

Single layer coating

Basic prep and correction

Premium package (full protection): $600-$1,000

All painted surfaces

Chrome and metal surfaces

Multi-layer coating

Paint correction included

Show/concours level: $1,000-$2,000

Complete surface correction

Premium coating products

Multiple coating layers

Extended warranty

RV Ceramic Coating Costs

Small RVs (Class B, under 25ft): $800-$1,500

Exterior gelcoat coating

Basic paint correction

Single or dual layer coating

Mid-size RVs (25-35ft): $1,500-$2,500

Full exterior coating

Moderate paint correction

Dual layer coating

Rubber roof treatment optional

Large RVs (35ft+, Class A): $2,500-$4,000

Complete exterior protection

Extensive paint correction

Multi-layer coating

Slide-outs and awnings included

Boat Ceramic Coating Costs

Small boats (under 20ft): $800-$1,500

Hull gelcoat coating

Topside surfaces

Basic oxidation removal

Mid-size boats (20-30ft): $1,500-$2,500

Complete hull and deck coating

Paint correction as needed

Multi-layer marine coating

Large boats (30ft+): $2,500-$5,000+

Full vessel coating

Extensive prep and correction

Premium marine-grade products

Multiple coating layers

Factors That Affect Cost

Surface condition:

Good condition: Base price

Light oxidation: +20-30%

Heavy oxidation: +50-100%

Size:

Price typically per square foot

Larger vehicles = higher cost

Surface types:

Single surface (paint only): Lower cost

Multiple surfaces (paint, chrome, plastic): Higher cost

Coating layers:

Single layer: Base price

Dual layer: +30-40%

Triple layer: +50-70%

Location:

Mobile service: May cost more

Shop service: More controlled, often better value

Coastal markets: Higher prices due to demand

Return on Investment

Protection value over 3 years:

Unprotected maintenance:

Wax every 2 months: $50-100 per session = $900-$1,800

One gelcoat restoration: $2,000-$4,000

Total: $2,900-$5,800

Ceramic coating:

One-time application: $800-$2,500

Minimal maintenance: $200-$400 over 3 years

Total: $1,000-$2,900

Savings: $1,900-$2,900 over 3 years, plus preserved resale value.

Maintenance Requirements

Ceramic coating isn't maintenance-free, but it's dramatically easier than wax or sealant.

Regular Washing

Frequency: Every 1-2 weeks for boats, 2-4 weeks for motorcycles and RVs

Proper technique:

Rinse thoroughly to remove loose dirt

Use pH-neutral car shampoo (not dish soap)

Wash with microfiber mitt, two-bucket method

Rinse completely

Dry with microfiber towels or air blower

Never:

Use automatic car washes on coated vehicles

Apply traditional wax or sealant over coating

Use harsh chemicals or degreasers

Pressure wash too close (keep 12+ inches away)

Decontamination

Every 3-6 months:

Clay bar treatment to remove bonded contaminants

Iron remover for rust particles

Tar and bug remover for organic deposits

This restores the coating's hydrophobic properties and maintains maximum protection.

Spray Boosters

Optional but recommended every 2-3 months:

Ceramic spray boosters refresh the top layer and add sacrificial protection. Products like:

Gtechniq C2v3

CarPro Reload

Ceramic Pro Silica Spray

These cost $15-$25 and take 15 minutes to apply. They significantly extend coating life.

Boat-Specific Maintenance

After every saltwater use:

Rinse with fresh water thoroughly

Remove any organic growth immediately

Check for bonded salt deposits

Monthly for saltwater boats:

Thorough wash with marine-safe shampoo

Inspect coating for damage or wear

Apply ceramic spray booster

Bottom cleaning:

Continue normal bottom cleaning schedule

Coating on hull makes cleaning easier

Reduces frequency of haul-outs needed

What Reduces Coating Life

Avoid these:

Harsh chemical cleaners (bleach, acetone, strong solvents)

Abrasive scrubbing pads or brushes

Automatic car washes with brushes

Leaving bird droppings or tree sap for days

Using wax, sealant, or tire shine on coated surfaces

Warranty Maintenance Requirements

Most professional coatings come with 2-5 year warranties that require:

Documented washing every 2-4 weeks

Annual inspection by installer

Use of approved maintenance products

Immediate reporting of damage or defects

Failure to maintain properly voids the warranty, so follow the requirements.

Key Takeaways

Essential points about ceramic coating for motorcycles, RVs, and boats:

Ceramic coating provides superior protection compared to wax or sealant, lasting 2-5 years instead of weeks

Different surfaces require different approaches - motorcycle paint, chrome, RV fiberglass, and boat gelcoat all need specific prep and products

Saltwater protection is critical for boats and coastal vehicles - ceramic coating blocks salt corrosion that destroys unprotected surfaces within months

UV protection extends gelcoat and paint life significantly - coating blocks 99%+ of UV rays that cause fading, chalking, and oxidation

Marine ceramic coating prevents gelcoat degradation - stops oxidation before irreversible damage occurs, saving thousands in restoration costs

Professional application is worth it for boats and RVs - high failure rate for DIY on large or complex vehicles

Proper maintenance is required - regular washing and decontamination every 3-6 months maintains coating effectiveness

ROI is excellent - one coating costs less than 2-3 years of regular waxing, plus prevents expensive restoration work

Not all coatings are the same - marine-grade and RV-specific formulations outperform automotive products on boats and RVs

Surface correction must come first - coating over oxidation or damage doesn't work; surfaces must be restored before coating

Frequently Asked Questions

Can I use the same ceramic coating on my motorcycle, RV, and boat?

Not recommended. While some coatings work across multiple surfaces, marine-grade coating is specifically formulated for saltwater and constant moisture exposure. RV fiberglass and motorcycle paint are better served by formulations designed for those surfaces. Using automotive coating on a boat typically results in shorter lifespan and reduced protection. Professional installers match coating chemistry to surface type for best results.

How long does ceramic coating last on boats in saltwater?

Quality marine ceramic coating lasts 2-3 years in saltwater with proper maintenance. This assumes regular freshwater rinsing after use and periodic decontamination. Unprotected boats need waxing every 2-4 weeks, so ceramic coating provides dramatically longer protection. Coating longevity depends on factors like sun exposure, water quality, how often the boat is used, and maintenance consistency.

Will ceramic coating prevent my RV gelcoat from oxidizing and chalking?

Yes, ceramic coating is extremely effective at preventing gelcoat oxidation. The coating blocks UV rays and prevents oxygen contact with the gelcoat surface, stopping the oxidation process that causes chalking. Existing oxidation must be removed through paint correction before coating. Once coated, gelcoat maintains its factory gloss and color for years instead of showing visible degradation within months.

Can I apply ceramic coating myself or should I hire a professional?

For motorcycles, experienced DIYers can get good results. For RVs and boats, professional application is strongly recommended. The large surface area, multiple surface types, and critical prep requirements make DIY challenging. Professional ceramic coating failure rate is under 5%, while DIY failure rate exceeds 40% on boats and RVs. Consider your experience level, available workspace, and vehicle value when deciding.

Does ceramic coating work on chrome motorcycle parts and exhaust pipes?

Yes, but chrome requires metal-specific primers or coating formulations. Chrome is non-porous, so standard ceramic coating won't bond properly without special prep. Professional installers use primers or chrome-specific coatings that create proper adhesion. Once applied correctly, ceramic coating prevents chrome oxidation, pitting, and discoloration better than any traditional chrome polish.

How much does it cost to ceramic coat a 35-foot RV?

Expect to pay $2,500-$4,000 for a 35-foot RV depending on surface condition and coating package. This includes paint correction, multi-layer coating application, and typically covers the exterior gelcoat surfaces. Heavy oxidation requiring extensive correction can increase costs by 50-100%. Additional costs may apply for rubber roof coating, slide-out protection, or premium multi-year coating products.

What's the difference between marine ceramic coating and automotive ceramic coating?

Marine ceramic coating is formulated for water immersion and saltwater exposure that automotive coating isn't designed to handle. Marine formulations include additional chemical resistance, stronger hydrophobic properties, and UV inhibitors specific to water environments. Using automotive coating on boats often results in premature failure, especially below the waterline or in saltwater. The price difference is typically 20-30% higher for true marine-grade products.

Can ceramic coating be applied over existing wax or sealant?

No, all wax, sealant, and previous coatings must be completely removed before ceramic coating application. Coating over these products prevents proper bonding to the surface, resulting in coating failure within weeks or months. Professional preparation includes chemical stripping, clay bar decontamination, and surface prep to ensure nothing interferes with coating adhesion. This is one of the most common causes of DIY coating failure.

Will ceramic coating prevent rock chips on my motorcycle or RV?

Ceramic coating provides limited rock chip protection—it's not a substitute for paint protection film (PPF). The coating hardens the surface and can prevent very minor impacts from chipping paint, but direct rock strikes at highway speeds will still cause chips. For maximum protection on motorcycles and RV front caps, combine ceramic coating with PPF on high-impact areas. The coating goes over PPF for easier maintenance and added protection.

Protecting Your Investment the Right Way

Ceramic coating for motorcycles, RVs, and boats isn't just about making your vehicle look good—it's about preventing thousands of dollars in damage from UV rays, saltwater, oxidation, and environmental contamination.

Whether you're protecting a $15,000 motorcycle, a $100,000 RV, or a $50,000 boat, the investment in ceramic coating pays for itself by preserving your vehicle's condition and resale value.

The key is understanding that different vehicles need different approaches. Motorcycle paint requires different prep than RV fiberglass. Boat gelcoat needs marine-grade protection that automotive products can't provide. Chrome and metal surfaces need specialized formulations.

Professional installation ensures you get the right products applied correctly with proper surface preparation. The coating will last years instead of failing within months like most DIY attempts.

If you're serious about protecting your motorcycle, RV, or boat from the elements, ceramic coating is the single best investment you can make.

Ready to protect your vehicle with professional ceramic coating? Contact Fresh Layer for a free consultation and quote. We specialize in surface-specific ceramic coating for motorcycles, RVs, and boats throughout San Diego County, with proven results in harsh coastal and high-UV environments. Our marine-grade coatings are formulated specifically for saltwater exposure and desert sun, providing protection that lasts years, not weeks.

With over 336 five-star reviews from satisfied San Diego vehicle owners, we've proven that proper ceramic coating makes the difference between surfaces that stay protected and those that deteriorate within months. Let us show you how professional ceramic coating can preserve your investment.